Mar. 11, 2022

Digital transformation is no longer a future state or something to reconsider for the next fiscal year, it’s an initiative that needs to be woven into the very fabric of an organization. After being awarded “2021 Foshan Digital and Intelligent Workshop”, as the benchmark for digital transformation in Foshan, Genteel showcased current DX achievements to visitors from 18 enterprises led by Danzao High-tech Enterprises association on February 25, 2022.

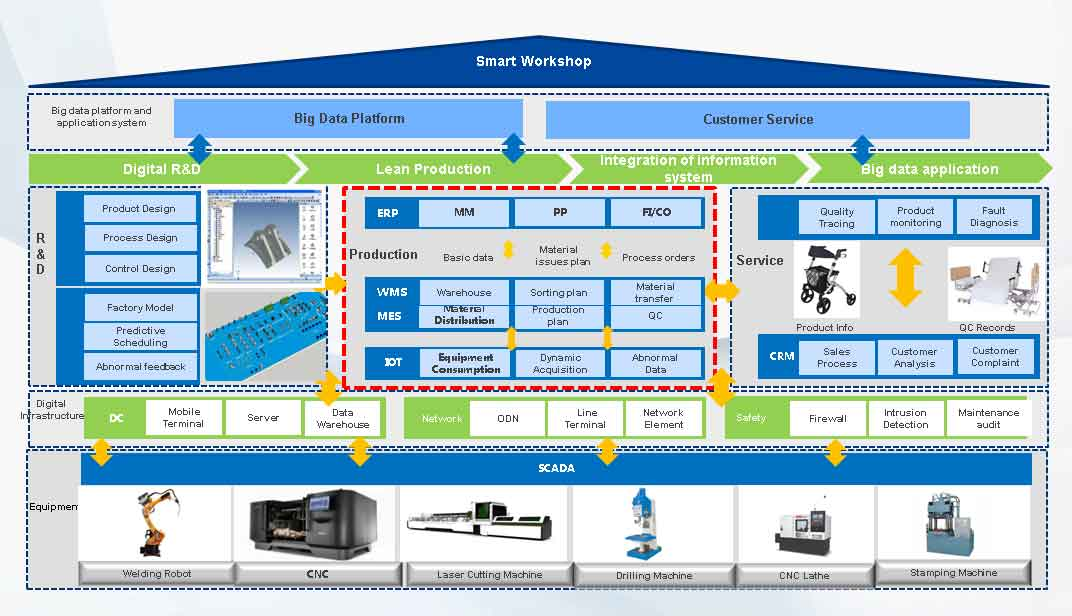

Li Chao, manager of the IT department, gave an introduction to the overall structure of the MES system, including production planning, material management, production execution, equipment management, and quality management. Meanwhile, he also shared the primary status, desired outcomes, and project implementation details of MES. He pointed out that lean production is the essence of the MES system, which enables to integrate of production, equipment, and quality management.

Mr. Zhang from XCMG IT Hanyun, presented the functional modules of the MES system applied to Genteel and expressed his hope on promoting MES to more enterprises to seek an effective way for production management, thereby realizing lean production.

During the visit, the town leaders and industry practitioners got a full picture of the changes brought to Genteel by launching the MES system.

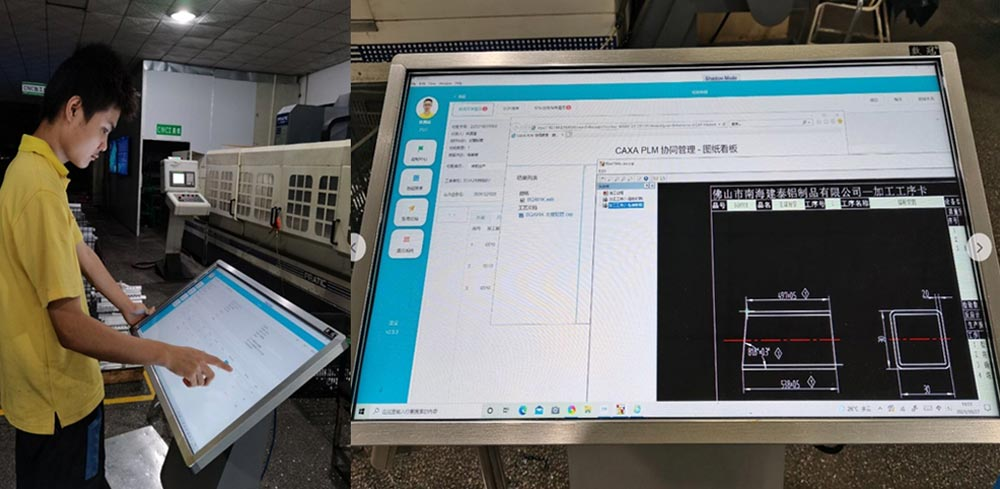

In the workshop, the electronic drawings are directly transmitted to the MES terminal, replacing traditional paper drawings, which greatly saved manpower and reduced mistakes on drawings management, at the meantime contributing to going paperless.

In the warehouse, the materials receiving process was completely manual, now the warehouse management is standardized with a coding system to ensure the efficiency and accuracy of warehouse operation.

Equipment and production data are collected and presented on Kanban in real-time, which makes the production process sharper by tracking and tracing end-to-end processes; the production capacity of each process can be balanced by subtilized production scheduling.

The town leaders fully affirmed the achievements Genteel has made in its smart manufacturing development and stressed that with the policies in full play, the government would make every endeavor to support Genteel to booster automation and transition. Genteel will actively pursue innovative solutions with perpetual vigor to enable the very best provision of the healthcare industry.